Received: 01-Nov-2022, Manuscript No. GJDFM-22-82679; Editor assigned: 03-Nov-2022, Pre QC No. GJDFM-22-82679 (PQ); Reviewed: 21-Nov-2022, QC No. GJDFM-22-82679; Revised: 30-Nov-2022, Manuscript No. GJDFM-22-82679 (R); Published: 07-Dec-2022, DOI: 10.15651/2449-1861.22.07.079

Condensed milk is produced using cow, buffalo, or a combination of both types of milk. Products made from condensed whole milk are packaged in cans for retail sales, whereas products made from sweetened condensed skim milk are bulk-packed in drums or barrels for use in confectioneries, bakeries, etc.

Producing sweetened condensed milk

Condensed milk is manufactured from standardised whole milk and contains sugar as a preservative. This is one among the earliest products to be commercially released. After removing 0.8 kg of water from each kilogram of milk, roughly 0.4 kg of product is left. Water can easily be added to the product to easily reconstitute it, yielding 2.5 kg of milk that has been sweetened from 1 kg of the product. The processes in processing that go into making sweetened condensed whole milk are listed.

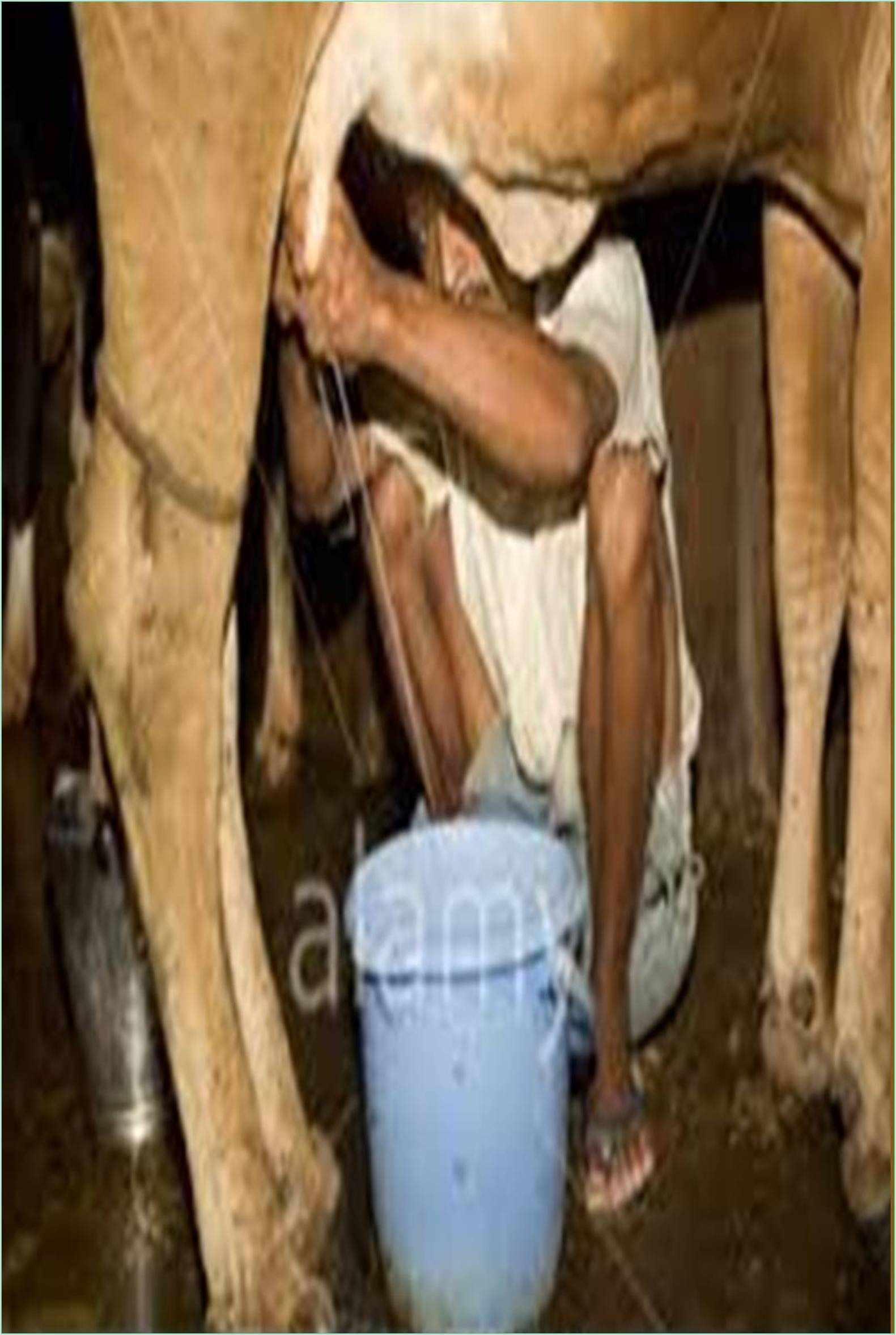

Receiving milk: Milk that will be used to make condensed milk needs to be clean, sweet, free of unpleasant flavors and odors, and reasonably free of foreign objects. There should be no acceptance of abnormal milk. To establish whether milk is acceptable for Condensing, platform tests including Alcohol and Clot-on-Boiling (CoB) tests must be conducted to evaluate the milk's heat stability.

Cooling: To stop the deteriorating effects of bacterial development, raw milk must be cooled as soon as it is received at the platform, to 5°C or lower.

Clarification/filtration: The removal of coarse particles, visible dust, or dirt from raw milk is done through filtration. Leucocytes, blood cells, and other minute feed particles are removed from milk during clarifying. Typically, standardization comes either before or after clarifying or filtering.

Standardization: Standardizing milk to the required fat is typically done to ensure that the completed product complies with legal criteria. Typically, skim milk or cream is added to raw milk to bring it up to standard.

Stabilization: The amount of heat treatment that milk can withstand before going through coagulation is referred to as its heat stability. The heat stability of milk is influenced by milk salts, particularly the proportion of calcium and magnesium to citrates and phosphates.

Since milk goes through a lot of heat processing to create condensed and evaporated milk, it's important to keep milk's salt balance at the recommended. Inadequate forewarning of milk and heat instability caused by high calcium and magnesium salts cause the product to thicken and gel during storage. Therefore, stabilization the process of adding tri sodium citrate or disodium phosphate should be used to reduce the amount of excess calcium and magnesium in milk. The high calcium content of buffalo milk necessitates the stabilization of salts during the conversion of buffalo milk into skim.

Fore warming aids in preventing product gelation and time of life thickening during storage. Additionally, it assists in destroying bacteria and supplying milk to the vacuum pan at a temperature high enough to avoid depressing boiling. The precise temperature-time of heating is adjusted to give the manufactured product the best viscosity possible without causing excessive thickening or thinning during storage.

Sugared condensed milk flaws

During storage, flaws in the sweetened condensed milk are caused by microbial development and physicochemical alterations. The growth of mould, yeast, and bacteria, respectively, causes a variety of microbiological problems, including buttons, gas generation, and thickening. Physical and chemical changes lead to flaws such browning and discoloration, cooked or stale flavors, age thickening, and gelation, which can be delayed by storing items at moderate temperatures. With the right fore warming and lactose crystallization conditions, other flaws including fat separation, thinning, sediment, and sandiness can be avoided during production.

Drying milk by spray

The most crucial technique for drying milk and milk products is the use of spray driers, which has expanded recently. Products should dry as rapidly and at a low temperature as possible. Liquid items can be dried in a matter of seconds by spraying a stream of hot air. As a result of the droplets' enormous surface area, the moisture quickly evaporates, leaving behind a highly soluble powder.